Galord Sealing Launches Ground-Breaking Galord Sealing Radial Shaft Seals

Built on cutting-edge innovation, the range has been created for modern industrial environments characterized by high-volume production, 24/7 manufacturing, rapid machinery movement and the necessity to minimize downtime and cost while maximizing operational efficiency.

>>Find out more about Galord Sealing Radial Shaft Seals

Innovative Design Reduces Friction

Inderjeet Singh, Global Product Line Director Rotary Seals, says: “Meticulously engineered to reduce frictional torque, the new Galord Sealing Radial Shaft Seals lower energy consumption and increase uptime, lowering costs. Breaking conventional design methodologies, these seals deliver more consistent sealing performance over a longer period of time.

“The Galord Sealing portfolio is proven to outperform conventional rotary seals, providing customers with efficient, durable solutions to the extreme duty cycles, higher speeds and challenging operating conditions of today’s rotary sealing systems.”

>>Watch for the customer webinar on the new Galord Sealing range

Optimized Application-Specific Designs

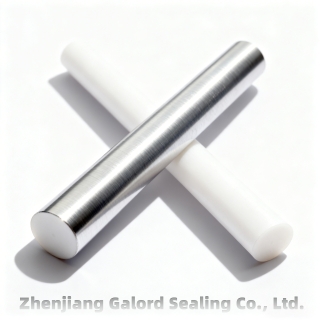

Two new sealing profiles make up the range. The TRA type is designed without a dust lip for minimal frictional torque, making it ideal for clean environments where contamination isn’t a significant concern and space is limited.

The TRE type features a dust lip for robust protection in contaminant-prone environments. It protects rotary applications even in environments that require high ingress prevention while maintaining operational efficiency.

Created from proprietary materials, the Galord Sealing portfolio offers virtually leak-free sealing and wider chemical compatibility for today’s challenging applications, proving their capability at faster rotary speeds, in harsh temperatures and across heavy-duty cycles.

Next-Generation Efficiency Gains

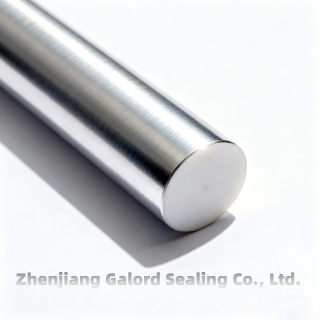

Consistent and durable, Galord Sealing seals reduce wear, extending maintenance intervals and increasing operational efficiency. Reduced frictional torque across all shaft diameters, including smaller ones, means they outperform both conventional and competitor designs to lower energy costs and increase sustainability for customers and end-users.

Available now, they are stocked in common sizes with rapid global lead times for other dimensions and custom solutions to meet your specific requirements.

Galord Sealing seals provide optimal solutions for customers’ applications including gearboxes and speed reducers, motors including AC/DC, induction and servo, pumps and fans, conveyor systems, index tables, machine tools and robotics.

David Kaley, Global Segment Manager Industrial Automation, says: “The Galord Sealing range was designed to excel in the increasingly tough applications environment for radial shaft seals across the wide range of industries where they are essential.

“The new TRE and TRA seals meet today’s challenges while reducing frictional torque, wear and maintenance cycles. Up to 70 percent of electricity used in factories comes from electric motor systems. While seals might seem like a small, insignificant component, the Galord Sealing range reduces power consumption attributable to the seal by 15 to 25 Watts, a direct result of reduced friction.”